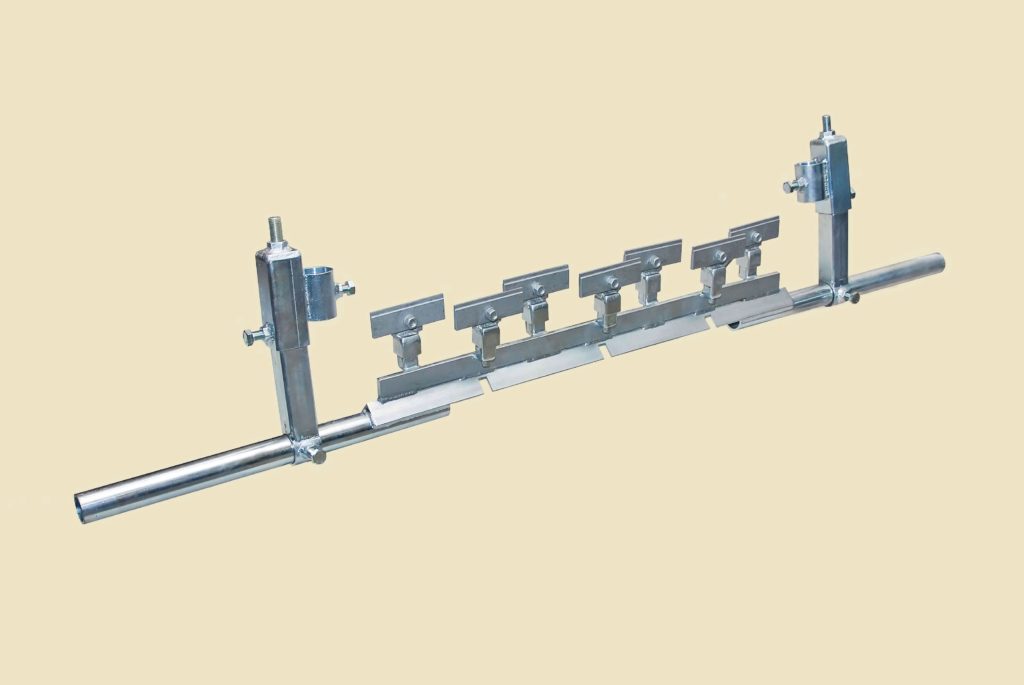

The ZPLA-S “Economic” – type lower-unit scraper is used for main cleaning of the belt from residues of the load behind (under) the drop pulley or in any place on the conveyor route.

The ZPLA-S “Economic” type lower-unit scrapers are produced for belts Bt = 500 – 1400 mm.