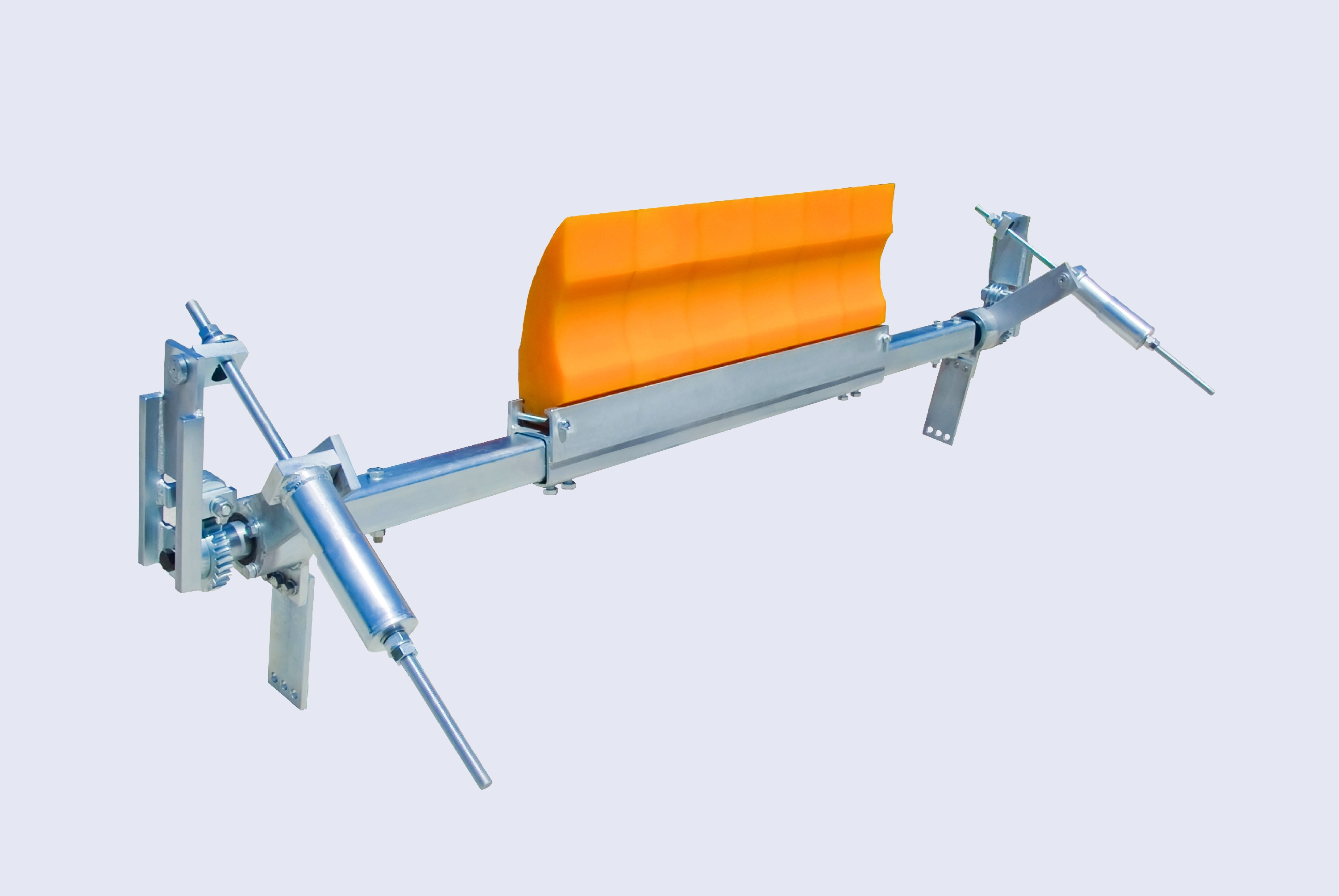

The front pulley scrapers, ZC-3-Super MAX “Prestige” – very heavy type, are designed for preliminary (in double systems) or main (in single systems) removal of load from the belt, eliminating a series of adverse phenomena such as pulley sticking, belt skid, belt slippage or belt destruction. They are installed in the front of the dump pulley.

The ZC-3-Super MAX “Prestige” – very heavy type scrapers are applied in extremely heavy duty services, especially when the belt’s speed is from 3.15 m/s to 8.00 m/s, dump pulleys have diameters of 1000, 1250, 1400 and 1600 mm, and load is very abrasive and highly granulated. Those scrapers are mainly designed for brown coal mines.

The ZC-3-Super MAX “Prestige” – very heavy type scrapers are manufactured for belts Bt=1600 – 2500 mm and are available with two spring tensioners connected with rotary discs with a steel cord.